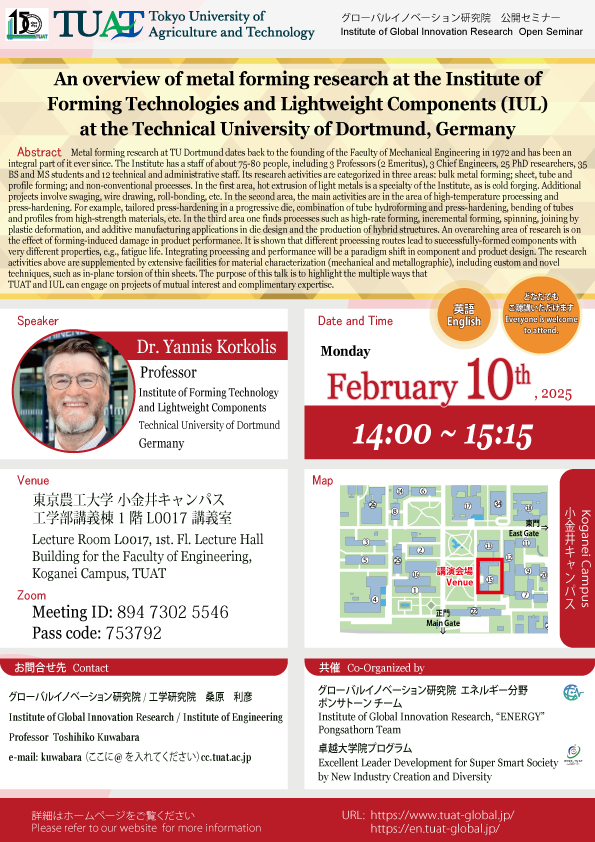

イベント情報

【GIR公開セミナー】Dr. Yannis Korkolis / ドルトムント工科大学(ドイツ)

| 日時 | 2025.2.10(14:00~15:15) |

|---|---|

| 会場 |

東京農工大学 小金井キャンパス 工学部講義棟 1 階 L0017 講義室 ミーティングID:894 7302 5546 パスコード:753792 |

| Google Classroom コード | b6imei3 |

| 講演者 | Dr. Yannis Korkolis |

| 所属機関 | ドルトムント工科大学 (ドイツ) |

| 講演タイトル | "An overview of metal forming research at the Institute of Forming Technologies and Lightweight Components (IUL) at the Technical University of Dortmund, Germany" <要旨> Metal forming research at TU Dortmund dates back to the founding of the Faculty of Mechanical Engineering in 1972 and has been an integral part of it ever since. The Institute has a staff of about 75-80 people, including 3 Professors (2 Emeritus), 3 Chief Engineers, 25 PhD researchers, 35 BS and MS students and 12 technical and administrative staff. Its research activities are categorized in three areas: bulk metal forming; sheet, tube and profile forming; and non-conventional processes. In the first area, hot extrusion of light metals is a specialty of the Institute, as is cold forging. Additional projects involve swaging, wire drawing, roll-bonding, etc. In the second area, the main activities are in the area of high-temperature processing and press-hardening. For example, tailored press-hardening in a progressive die, combination of tube hydroforming and press-hardening, bending of tubes and profiles from high-strength materials, etc. In the third area one finds processes such as high-rate forming, incremental forming, spinning, joining by plastic deformation, and additive manufacturing applications in die design and the production of hybrid structures. An overarching area of research is on the effect of forming-induced damage in product performance. It is shown that different processing routes lead to successfully-formed components with very different properties, e.g., fatigue life. Integrating processing and performance will be a paradigm shift in component and product design. The research activities above are supplemented by extensive facilities for material characterization (mechanical and metallographic), including custom and novel techniques, such as in-plane torsion of thin sheets. The purpose of this talk is to highlight the multiple ways that TUAT and IUL can engage on projects of mutual interest and complimentary expertise. |

| 言語 | 英語 |

| 対象 | どなたでも、ご参加いただけます。 |

| 共催 | グローバルイノベーション研究院 エネルギー分野 ポンサトーン・ラクシンチャラーンサク チーム 卓越大学院プログラム |

| お問い合わせ窓口 | グローバルイノベーション研究院・工学研究院 桑原利彦 e-mail: kuwabara ( ここに@ を入れてください) cc.tuat.ac.jp |

| 備考 | 本セミナーは、オンライン・対面型の同時開催となります。 |

このページの上部へ